Optimum capture of produced quality

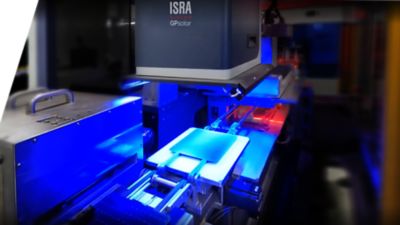

The TEX-Q inspection system precisely monitors the cell surface for contamination and defects, while also checking the texture for homogeneity and reflectivity. It features high-performance line-scan cameras that uncover defects like long-term drifts or overetching of grain boundaries, even at a throughput of several thousand wafers per hour. The cameras can also be fitted beneath the roller transport.

The system reliably monitors the quality of every produced cell, assigning defects to the respective wafer position. The map generated during this process (“Boat View”) then visualizes the potential for optimization in the event of process deviations. As a result, users can quickly counteract any deviations and directly reduce waste. Furthermore, the system enables users to automatically remove wafers that do not meet the classification thresholds, thereby avoiding cost-intensive further processing. TEX-Q offers reliable process monitoring that guarantees efficient production, reduces production costs on the line, and optimizes the quality of the solar wafers produced.

TEX-Q solutions are powered by

- Texturing quality monitoring: Inspection of homogeneity and reflectivity

- Suitable for every texture: alkaline, acidic, MCCE (black silicon)

- Check for contaminations and defects, longterm drifts

- On-thy-fly inspection for cycle times <0.7 sec and highest throughputs

- Connected PV "boat view": trace back faulty cells to carrier, machine, and chemical bath

- Inspection of wafer sizes from M6 to M12+