Reliable pattern inspection for solar cells

The metallization of solar cells is one of the most demanding steps in the production processes: Contact structures are often very thin, and new cell technologies require highest accuracy for positioning of the contacts. At the same time, weaknesses of the metallization process have more influence on the yield than many others do.

Monitoring the quality of the metallization structures with PRINT-Q significantly reduces production costs by identifying process weaknesses in time. Users can directly optimize their processes before yield loss occursThe inline inspection tool evaluates the metallization process in terms of positioning and quality of the metallization structures.

It reliably detects defects, such as finger interruptions or finger thickenings, as well as stains and smearings, or ghost plating an finger peeling, directly after screen printing or plating:

Finger, closing: Interrupts, thinnings, slubs, nodes, paste stains and smearings

Busbars: absent segment

Measurement of local fingerwidth, incl. probe regions for comparison with offline data

Measurement of grid position, grid distances, busbar positions

Optimized illumination conditions allow for contact pattern inspection on glossy surfaces and alignment control of the laser or IBC contact structures, and contact patterns. High defect contrasts and low background noise minimize overkill and underkill for all solar cell technologies (such as Perc, IBC,…).

Full support of central recipe management

With Connected PV, print recipes are managed centrally and rolled out to every single PRINT-Q system with a mouse click. This minimizes user errors, significantly shortens installation times, and ensures consistent quality settings on all lines.

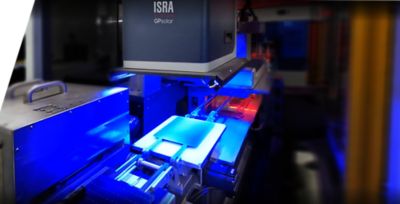

Print or plating monitoring at the smallest footprint

PRINT-Q is easy to integrate into any screen printing or plating system, and can even be retrofitted within the smallest space. The collected data can also be transferred to the screen printer to readjust the printing position automatically.

PRINT-Q solutions are powered by

- Inspection of the print/pattern features, based on a CAD like model of the grid pattern

- Detection of print/pattern features and deviations, alignment control via fiducials

- Stop & go or on the fly print pattern inspection of solar cells

- < 0.7 sec cycle time for single image (print and fiducials only) in PRINT-Q SE

- < 0.6 sec cycle time for single image (print and fiducials) in PRINT-Q Scan