Optimized processes and reduced waste with full edge inspection

After grinding, the edge inspection system P2-Edge checks the edges of the glass for all typical edge and grinding defects, such as cracks, chips, shiners, and burn marks. It is the only system on the market to detect asymmetries in the grind early on, optimizing the process and preventing waste.

The data collected can be used to determine the ideal replacement time for the grinding wheel and edge cutter.

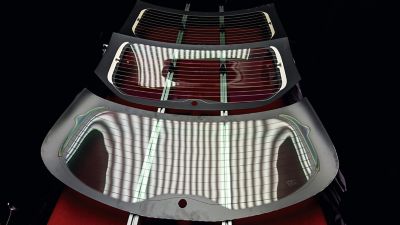

There are various ways to integrate the high-precision edge inspection sensors into the production line. Each sensor scans an edge with multiple high-resolution cameras and special illumination systems that enable an all-round view of the edge. The system analyses the generated images in real time, detecting and classifying all edge defects. This enables automatic quality classification of the panels.

- All around acquisition of the glass edge at a glance

- Suitable for use with a robot

- Real-time image acquisition

- Robust and compact

- Narrow construction style

Download additional information

Automotive Overview brochure

Automotive Overview brochure

P² (PowerPlate) Edge flyer en

- Filename

- flyer-powerplate-p2-edge-glass-en.pdf

- Size

- 723 KB

- Format

P² (PowerPlate) Edge flyer cn

- Filename

- flyer-powerplate-p2-edge-glass-cn.pdf

- Size

- 855 KB

- Format