High quality and safety of automotive glass

The automotive glass manufacturing process includes various issues that can impair the quality and safety of windshields. One of the biggest challenges is achieving the desired thickness and flatness of the glass during the melting and shaping process. Any deviation from the desired specifications can lead to defects that can weaken the glass, making it unable to withstand stresses such as impacts from potholes, road debris or temperature fluctuations.

Throughout the manufacturing process, there are various defects that can affect the quality and safety of windscreens, such as impurities or foreign objects getting trapped in the glass, and defects in the glass surface or structure.

These defects can result in the driver's vision being restricted, structural integrity being compromised, or even the windshield breaking.

ISRA VISION inline surface inspection detects and classifies all defects and ensures that the highest quality specifications for windshields are met.

Quality Inspection

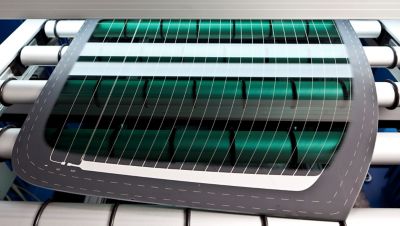

Our in-line optical inspection systems perform a complete quality inspection on all kinds of automotive glass panes, from rectangular to free-form glass, including clear and privacy glass as well as silkscreen printed glass panes. Suitable for all pane sizes and thicknesses, the systems inspect the entire panel, as well as the edges.

The systems reliably identify the tiniest scratches even at high-speed conveying, classify quality-related defects and prevent further processing of defective products ensuring a quick return on investment.

After grinding, the edge inspection system checks the edges of the glass for all typical edge and grinding defects, such as cracks, chips, shiners, and burn marks. The high-precision sensors detect and classify all defects in real time and enable the determination of the ideal replacement time for the grinding wheel and edge cutter.

The in-line optical inspection systems can be integrated into any process environment and can be adjusted to any glass type. Analysis functions for process optimization guarantee high quality, flawless products, resulting in increased customer retention, permanently reduced production and downtime costs.

Benefits

- Fast and seamless integration into existing process lines

- No adaption of production process required

- High speed inspection

- Zone based quality grading

- Production process analysis and improvement

- Ready for Industry 4.0

- Features

- Typical defects

- In-line inspection at the highest sensitivity

- Fine scratch detection

- Severity check

- Panel shape measurement and Inspection zone definition

- Customized quality grading

- Statistics and analysis tools for process optimization

- Absorbing defects in glass area

- Transmitting defects in print area

- Missing or extended print

- Transmission and position of shade band

- Existence and position of markers and logos

- Edge and grinding defect

Download additional information

- English

- Chinese

Brochure Automotive Glass [EN]

- Filename

- brochure-automotive-glass-en.pdf

- Size

- 961 KB

- Format

Flyer P² (PowerPlate) Edge [EN]

- Filename

- flyer-powerplate-p2-edge-glass-en.pdf

- Size

- 723 KB

- Format

Brochure P² (Powerplate)-INSPECT [EN]

- Filename

- brochure-p2-inspect-glass-en.pdf

- Size

- 514 KB

- Format

Brochure SCREENSCAN INSPECT [EN]

- Filename

- brochure-screenscan-inspect-glass-en.pdf

- Size

- 241 KB

- Format

Brochure Automotive Glass [CN]

- Filename

- brochure-automotive-glass-cn.pdf

- Size

- 1 MB

- Format

Flyer P² (PowerPlate) Edge [CN]

- Filename

- flyer-powerplate-p2-edge-glass-cn.pdf

- Size

- 855 KB

- Format

Brochure P² (Powerplate)-INSPECT [CN]

- Filename

- brochure-p2-inspect-glass-cn.pdf

- Size

- 688 KB

- Format

Brochure SCREENSCAN INSPECT [CN]

- Filename

- brochure-screenscan-inspect-glass-cn.pdf

- Size

- 413 KB

- Format

Optical Power Measurement

Optical Power Measurement is an essential factor in automotive glass production to ensure that the glass meets the desired specifications for clarity and visual acuity. By measuring the refractive index of the glass, which is the degree to which it bends light, manufacturers can assess the quality and consistency of the glass.

Our automated inspection systems are designed for the inspection of optical defects and shape deviations on reflective and curved surfaces. Developed for use in quality and design laboratories, they precisely inspect optical distortions and the curvature quality of all types of automotive glass.

Measurement of optical distortions

The systems fully analyze all glass and panel types measuring the horizontal and vertical transmitted optical distortions. Using special filters, they accurately identify defect causes in the production process while clearly displaying the recorded inspection results using color coding. This guarantees production quality while also ensuring the optical quality of the ADAS (Automatic Driver Assist Systems) function.

Equipped with ISRA's patented Moiré technology, the inspection systems perform repeatable measurements across the entire panel surface and reliably detect distortions down to the millidiopter range. In a single measurement process, they capture the smallest defects and classify them according to objective criteria. This enables the traceability of production defects and the rejection of defective glass panes.

Evaluation of the curvature quality

Specially developed 3D measurement systems evaluate the curvature quality of all automotive glass types. Based on stereo deflectometry the systems reliably and automatically measure the local curvature on reflective surfaces with high precision in millidiopters.

With ISRA VISION quality inspection systems, you can monitor your processes in detail and simultaneously receive an analysis of the quality criteria. Based on the collected measurement data, you can analyze and optimize the production processes.

Depending on the requirements, we offer inline inspection systems for real-time operation during production or offline inspection for quality control after production.

Benefits

- Reliable, objective and repeatable measurement results in diopter

- Reliable and repeatable measurement of transmitted distortion instead of subjective visual methods

- Production process optimization

- Fast and precise data acquisition

- Reliable and repeatable measurement of transmitted distortion instead of subjective visual methods

- Quick and easy visualization of results, user-friendly operation

- Certified by renowned global car manufacturers for the compliance of their technical specifications

- Features

- Typical defects

- 100% in-line quality control on production lines

- ADAS evaluation tools

- Measurements within production cycle-time

- Non-contact optical 3D-measurement

- Optional: measurement of double-vision

- Real-time target performance verification to CAD data

- Horizontal and vertical distortions

- Shape deviations

- Poor curvature quality

- Bubble, Scratch, Inclusion

- Print and coating defects

Download additional information

- English

- Chinese

Brochure Automotive Glass [EN]

- Filename

- brochure-automotive-glass-en.pdf

- Size

- 961 KB

- Format

Flyer LABSCAN-Screen [EN]

- Filename

- flyer-labscan-screen-glass-en.pdf

- Size

- 263 KB

- Format

Flyer SCREENSCAN-Faultfinder [EN]

- Filename

- flyer-screenscan-faultfinder-glass-en.pdf

- Size

- 1 MB

- Format

Brochure SCREENSCAN INSPECT [EN]

- Filename

- brochure-screenscan-inspect-glass-en.pdf

- Size

- 241 KB

- Format

Brochure SCREENSCAN-Reflected Distortion [EN]

- Filename

- brochure-screenscan-reflected-distortion-glass-en.pdf

- Size

- 699 KB

- Format

Brochure Automotive Glass [CN]

- Filename

- brochure-automotive-glass-cn.pdf

- Size

- 1 MB

- Format

Flyer LABSCAN-Screen [CN]

- Filename

- flyer-labscan-screen-glass-cn.pdf

- Size

- 403 KB

- Format

Flyer SCREENSCAN-Faultfinder [CN]

- Filename

- flyer-screenscan-faultfinder-glass-cn.pdf

- Size

- 286 KB

- Format

Brochure SCREENSCAN INSPECT [CN]

- Filename

- brochure-screenscan-inspect-glass-cn.pdf

- Size

- 413 KB

- Format

Brochure SCREENSCAN-Reflected Distortion [CN]

- Filename

- brochure-screenscan-reflected-distortion-glass-cn.pdf

- Size

- 818 KB

- Format

Production analytics - Data-driven efficiency

The web-based production analytics platform allows you to check the system status of all production lines at a glance or analyze production data in detail. With the quality management system, you analyze historical data, monitor current inspection data in real-time, and identify future trends in your production process.

Early detection of production defects

Detect and quickly identify the cause of threshold value violations at every stage of production with live status information and automatic alerts. As a result you can quickly resolve production defects, shorten downtime, and reduce production costs.

Predictive maintenance

You can prevent potential system failures by analyzing real-time data from the sensors and monitoring systems. This allows proactive planning of maintenance, based on the actual condition of the machines, instead of following a fixed schedule. This data-driven approach saves costs through reduced downtime and increased overall productivity, as well as longer production line life.

Optimization of production

Dashboards allow you to compare production line and product data onsite or remotely, providing key insights for optimization. This enables you to make informed professional decisions along your value chain to increase the product quality as well as profitability. You can continuously track the progress of optimization measures and present them with visualized advanced reports.

Your benefits

- Time-saving multi-line overviews, one view for all quality-related information

- Minimize downtime by monitoring system health data

- Faster reaction to quality issues with quality data monitoring

- Fast elimination of production defects, reduction of production costs

- Improved maintenance for reduced downtime, higher overall productivity and longer production line life

Key Features

- Overview on production data and plant status

- Live insights from real time data

- Department oriented dashboards, customer specific adaptations are possible

- Web-based solution, no client software installation required

- Threshold monitoring and alerting

- Open to integrate relevant third-party data and export data to the customer's systems

Service solutions and individual trainings

For the efficient and future-proof operation of your production systems our highly qualified service teams support you globally in all matters. We provide the implementation, maintenance and servicing as well as the analysis and optimization of your systems.

Learn in the ISRA VISION Academy how our competent trainers always keep your employees up to date with the latest knowledge so that system operators, product engineers and quality managers become real inspection experts.