3D automated inline metrology and robot guidance solutions

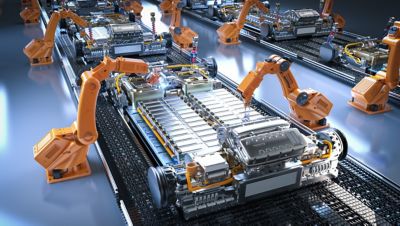

Since 1981, Perceptron has been at the forefront of 3D automated inline metrology and precision robot guidance solutions. Through groundbreaking machine vision development and pioneering engineering, Perceptron created an innovative measurement solution that efficiently addressed quality issues as they arose while proactively reducing process variation.

This led to the creation of the first viable, in-process, 100%-dimensional measurement solution capable of thriving in the most demanding manufacturing environments.

In 2020, Perceptron joined the Atlas Copco Group, solidifying its role as the industrial metrology expert within the Machine Vision Solution (MVS) division and under the ISRA VISION brand.

By combining resources and expertise, the MVS division has streamlined operations, delivering an enhanced customer experience, superior product quality, accelerated innovation, and new opportunities for growth and development. Together, we are setting new standards in the industry, driving excellence, and shaping the future of metrology.

- Solutions

- Products

- Service & Support

Software security notifications

Would you like to receive notifications about software security disclosures?

Fill out the form below to be added to a software security distribution list. This will provide notification of uncovered security vulnerabilities for the Vector software product and applied third-party components.