We build partnerships for tomorrow‘s technological excellence

ISRA VISION forms the core of the Machine Vision Solutions (MVS) division within the Atlas Copco Group. We develop, install and service an extensive range of solutions for surface inspection, robot guidance, quality inspection and automated metrology. We are active in a wide range of industries and markets with a global sales- and service network. These are key for our customers in enabling digital and flexible automation as well as respond to increased quality demands from their customers.

Machine Vision – Highest quality, increased output at lower costs

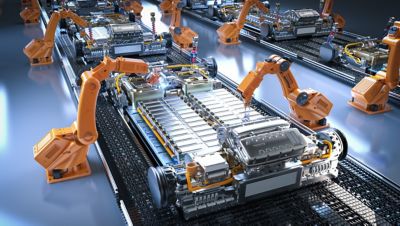

Machine vision is a technology that utilizes cameras, sensors, special lighting and advanced algorithms to automatically inspect, analyze, and interpret visual information in a manufacturing process, enhancing efficiency, accuracy, and quality control.

Our machine vision solutions use state-of-the-art technologies to perform precise and reliable inspection, measurement and robot guidance tasks.

For surface inspection, we use high-resolution cameras and advanced LED lighting for optimal contrast and visibility of defects. These systems detect and classify surface defects and anomalies reliably with high accuracy using deep learning technologies, resulting in superior product quality and consistency for our customers.

Our automated metrology solutions provide advanced optical gaging and non-contact laser triangulation technologies. These systems enhance part inspection accuracy and throughput by providing high-quality measurement data, and ensure our customers consistently meet stringent quality standards in various industrial applications.

For robot guidance applications, robots equipped with point cloud sensors enable precise component localization and accurate positioning. Utilizing sophisticated algorithms and sensor technologies, they ensure that robots perform tasks with utmost accuracy and efficiency. For our customers, this leads to higher productivity and flexibility in part handling.

Our software solutions feature advanced algorithms for image processing, pattern recognition and machine learning. These algorithms enable real-time decision making and adaptive control, which is essential for maintaining high productivity and quality assurance.

How ISRA VISION supports customer success

Customers benefit from a broader range of products and solutions. The Atlas Copco Group offers an extensive range of industrial tools and solutions that can often be combined with our machine vision solutions.

Global presence and customer support

The Atlas Copco Group has a global network of distribution centers that now also benefit ISRA VISION. Customers can access comprehensive support and service.

Optimized integration of technologies

The integration of ISRA VISIONS' technologies with Atlas Copco Group's existing solutions enable efficient and seamlessly integrated industrial processes. In this way, we support our customers in increasing their productivity and saving costs.

Innovative strength and technological leadership

Being part of the Atlas Copco Group creates synergies. Driven by the bundling of innovative forces, technological developments are accelerated. This allows our customers to benefit from the most advanced solutions.