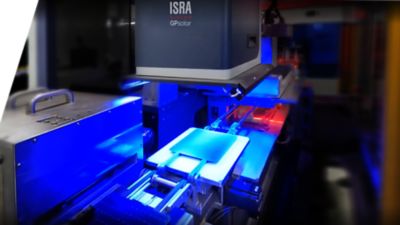

High-precision geometric measurement for maximum throughput

Edge distortions and geometric irregularities are detected in cycle times of less than one second. The inspected wafers are sorted into different quality classes based on their geometric properties. Wafers that do not meet the desired quality can thus be removed before further processing – ensuring high quality for excellent module effectiveness and permanently reduced warranty costs.

With the “Copy-Exact” calibration concept, users can also transfer inspection recipes and settings quickly between production lines. This ensures a uniform inspection standard and reduces the system set-up workload.

GEO-Q solutions are powered by

- Geometry measurement and contour inspection for photovoltaic wafers

- Captures one single matrix image on the fly

- Support for half-cut samples - two samples in a single camera image

- Dimensional check (edge lengths, angles, chamfer lengths, chamfer angles)

- Contour defects (Intrusions, V-Breaks, Breakage, chamfer breakage)

Download additional information

Automotive Overview brochure

Automotive Overview brochure

Automotive Overview brochure

- Filename

- brochure-automotive-a4-cn.pdf

- Size

- 2 MB

- Format

Automotive Overview brochure de

Automotive Overview brochure de

- Filename

- brochure-automotive-a4-de.pdf

- Size

- 2 MB

- Format

Automotive Overview brochure en

Automotive Overview brochure en

- Filename

- brochure-automotive-a4-en.pdf

- Size

- 2 MB

- Format