Top quality of security substrates & printing

Security papers, security films, security elements and security printing must adhere to rigorous quality standards for perfect counterfeit protection. Sub-standard quality and defects result in costly complaints and rejects. Therefore, compromising manufacturing precision significantly reduces productivity and revenue.

Learn how to achieve the highest inspection reliability for security paper, security foil and all applied security elements along with a short ROI, fast setup and easy operation.

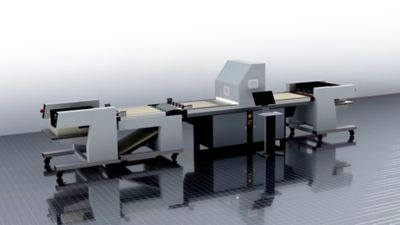

The BankSTAR product line is the only inspection system specifically tailored to the requirements of the security printing and substrates industry. It provides the highest inspection reliability for security paper, security foil and all applied security elements.

Enjoy the confidence of 100% substrate inspection from the global #1 in banknote paper inspection and obtain unsurpassed holography inspection performance, trusted by the leading manufacturers of security threads and diffractive security features.

BankSTAR secures quality by inspecting the surface and security elements of the material. Defects are identified at the earliest possible stage. Productivity is optimized by excluding sub-standard material from further processing. High-end technology components deliver precise and reliable inspection results at any stage within the production process.

But, BankSTAR serves not only as an high-end inspection tool before shipping to your customer, the different systems also help to significantly optimize production efficiency and reduce costs.

BankSTAR in-line inspection systems can also go on a conveyor/sorter platform to make an autonomous stand-alone solution.

Recent additions to our constantly growing BankSTAR solutions portfolio include:

Enhanced Threads Inspection add-on

Finally, there is a solution to what previously had been beyond the scope of in-line automated optical inspection: The Enhanced Threads Inspection add-on for our acclaimed BankSTAR banknote paper inspection verifies the manufacturing quality of embedded and windowed security threads.

Besides the up to 16 checks on security paper thread zones that BankSTAR has been performing anyway, revolutionary new algorithms are now employed to verify the thread décor for defect-freeness, detect thread slitting errors and trace thread fluorescence.

The Enhanced Threads Inspection add-on thereby not only cures a major headache of security paper manufacturers, as security threads cannot be subjected to an incoming inspection before they are inserted into the substrate, but also has the potential of saving paper mills hundreds of thousands of Euro in rejections and wastage due to flawed thread quality.

The Enhanced Threads Inspection add-on makes this quantum leap in banknote paper inspection available to paper makers with just a minor hardware upgrade – mainly, an extra PC for running the additional algorithms – and a quick and easy software update.

Enhanced Threads Inspection is available for BankSTAR Gen4, our latest product generation, and can be deployed at the wet section or dry end of the paper mill, as well as at the cross-cutter.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Low maintenance requirements

- Avoid adding value to waste material

- Defect detection on security paper, security foil and on all applied security elements

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

asdf

asdf

BankSTAR brochure en

- Filename

- brochure-bankstar-security-en.pdf

- Größe

- 1 MB

- Format

test123

test123

BankSTAR gen4 brochure en

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Größe

- 399 KB

- Format

BankSTAR brochure cn

- Filename

- brochure-bankstar-security-cn.pdf

- Größe

- 2 MB

- Format

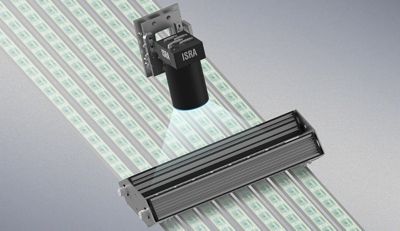

BankSTAR Color: Off-color detection

The detection of off-colors has been an increasing concern of security paper manufacturers. Fluorescent security fibers and extremely low-contrast stains do not differ from the substrate or from one another by grey value, but only by color. Adherence to rigorous quality standards and customer demands therefore requires color evaluation alongside contrast-based inspection.

BankSTAR Color allows the free defintion of color spaces to distinguish between correct colors and off-colors. Unwanted security fibers - visible or UV-reactive - are faithfully detected by dedicated hardware processing in near real-time at even the highest web speeds. Correctly colored security fibers are tolerated. By the same token, oil stains and other off-color contaminations are found even if their grey value is the same as the substrate's.

BankSTAR Color is the perfect companion for BankSTAR WS, PM, OV and CC, adding a one-of-a-kind color feature to security substrate inspection.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Low maintenance requirements

- Avoid adding value to waste material

- Defect detection on security paper, security foil and on all applied security elements

- Features

- Typical defects

- Technical data

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

- Technical data 1

- Technical data 2

- Technical data 3

- Technical data 4

- Technical data 5

Download additional information

BankSTAR brochure en

- Filename

- brochure-bankstar-security-en.pdf

- Größe

- 1 MB

- Format

BankSTAR gen4 brochure en

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Größe

- 399 KB

- Format

BankSTAR brochure cn

- Filename

- brochure-bankstar-security-cn.pdf

- Größe

- 2 MB

- Format

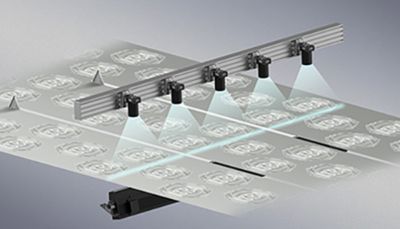

BankSTAR RS: Sheet format inspection

This innovative new inspection solution helps to optimize the trim position of the roll slitter with sheet format inspection.

Incorrectly cut paper rolls lead to significant waste and reduce your throughput – lowering both productivity and yield.

BankSTAR RS ensures exact position control of slitting and trim. It detects even the smallest object positioning deviations and defects.

BankSTAR RS is the only solution for performing format inspection on the roll slitter that helps you avoid waste, increase productivity and gain process control.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Defect detection on security paper, security foil and on all applied security elements

- Low maintenance requirements

- Avoid adding value to waste material

- Inspection at highest processing speeds and real-time classification

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

BankSTAR brochure en

- Filename

- brochure-bankstar-security-en.pdf

- Größe

- 1 MB

- Format

BankSTAR gen4 brochure en

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Größe

- 399 KB

- Format

BankSTAR brochure cn

- Filename

- brochure-bankstar-security-cn.pdf

- Größe

- 2 MB

- Format

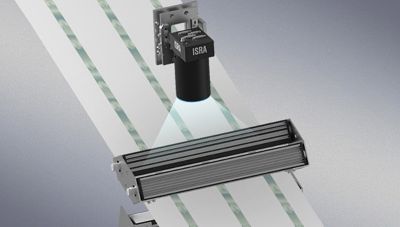

BankSTAR TS: Thread slitting inspection

Automate optical inspection on the thread slitter with a highly specialized thread inspection behind the slitting knife. This new inspection system inspects both the slitting position and the content of the threads on the pancake roll.

The special image-processing algorithm checks each thread separately, tolerating thread oscillation. This enables perfect quality control as each single thread is checked for immaculate quality.

In addition, perfect process control helps re-adjust the knife before the slitting position goes out of tolerance. Reduce quality claims and the associated cost by ensuring that only material meeting your customer´s quality standards is passed along the process chain and shipped.

Benefits

- Low maintenance requirements

- Short ROI, quick setup, easy usability

- Defect detection on security paper, security foil and on all applied security elements

- Avoid adding value to waste material

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

BankSTAR brochure en

- Filename

- brochure-bankstar-security-en.pdf

- Größe

- 1 MB

- Format

BankSTAR gen4 brochure en

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Größe

- 399 KB

- Format

BankSTAR brochure cn

- Filename

- brochure-bankstar-security-cn.pdf

- Größe

- 2 MB

- Format

Production Analytics

Die webbasierte Production Analytics Plattform ermöglicht es Ihnen, den Systemstatus aller Produktionslinien auf einen Blick zu überprüfen oder Produktionsdaten im Detail zu analysieren.

Mit dem Qualitätsmanagementsystem analysieren Sie historische Daten, überwachen aktuelle Prüfdaten in Echtzeit und ermitteln zukünftige Trends in Ihrem Produktionsprozess.

Optimierung der Produktion

Über Dashboards können Sie die Daten der Produktionslinie und des Produkts vor Ort oder von unterwegs aus vergleichen und erhalten so wichtige Erkenntnisse für die Optimierung. So treffen Sie fundierte Entscheidungen entlang Ihrer Wertschöpfungskette, um die Produktqualität und die Rentabilität zu steigern. Die Fortschritte der Optimierungsmaßnahmen können Sie kontinuierlich verfolgen und mit visualisierten, erweiterten Berichten darstellen.

Frühzeitiges Erkennen von Produktionsfehlern

Grenzwertüberschreitungen können Sie in jedem Produktionsschritt, mithilfe von Live-Statusinformationen und automatischen Warnmeldungen schnell erkennen und deren Ursache finden. Damit lösen Sie Produktionsfehler schnell, verkürzen Ausfallzeiten und senken die Produktionskosten.

Vorausschauende Wartung

Potenzielle Anlagenausfälle können Sie durch die Analyse von Echtzeitdaten aus den Sensoren und Überwachungssystemen verhindern. Dies ermöglicht eine proaktive Planung der Wartung, die auf dem tatsächlichen Zustand der Maschinen basiert, anstatt einem festen Zeitplan zu folgen. Dieser datengestützte Ansatz spart Kosten durch geringere Ausfallzeiten und erhöht die Gesamtproduktivität sowie die Lebensdauer der Produktionslinie.

Ihre Vorteile

- Zeitsparende mehrzeilige Übersichten, eine Ansicht für alle qualitätsbezogenen Informationen

- Minimierung von Ausfallzeiten durch Überwachung der Systemzustandsdaten

- Schnellere Reaktion auf Qualitätsprobleme durch Überwachung der Qualitätsdaten

- Schnelle Beseitigung von Produktionsfehlern, Reduzierung der Produktionskosten

- Verbesserte Wartung für geringere Ausfallzeiten, höhere Gesamtproduktivität und längere Lebensdauer der Produktionslinie

Funktionen

- Überblick über Produktionsdaten und Anlagenstatus

- Webbasierte Lösung, keine Installation von Client-Software erforderlich

- Abteilungsbezogene Dashboards, kundenspezifische Anpassungen sind möglich

- Live-Einblicke aus Echtzeitdaten

- Offen für die Integration relevanter Drittdaten und den Export von Daten in die Systeme des Kunden

- Schwellenwertüberwachung und Alarmierung

Servicelösungen und Schulungen

Für den effizienten und zukunftssicheren Betrieb Ihrer Produktionsanlagen unterstützen Sie unsere hochqualifizierten Serviceteams weltweit in allen Belangen. Wir übernehmen die Implementierung, Wartung und Instandhaltung sowie die Analyse und Optimierung Ihrer Anlagen.

Lernen Sie in der ISRA VISION Academy, wie unsere kompetenten Trainer Ihre Mitarbeiter immer auf dem neuesten Stand des Wissens halten, damit Anlagenbediener, Produktingenieure und Qualitätsmanager zu echten Inspektions-Experten werden.